Why Fashion Became the World’s Third Most Polluting Industry

Sustainable Style & Fashion May 17, 2024

The fashion industry ranks as the third most polluting sector worldwide. Shockingly, it stands as the second largest water consumer, trailing only agriculture. Astonishingly, 20% of water pollution results from textile dyeing and finishing processes. Alarming statistics reveal that the industry contributes a staggering 92 million tons of textile waste annually, primarily ending up in landfills. Moreover, the burning of synthetic textiles releases harmful chemicals into the atmosphere, including dangerous dioxins and furans. To make matters worse, microplastics stemming from clothing pollution have infiltrated our oceans, rivers, and even the very air we breathe. It begs the question: Have any of us paused to consider why such a colossal environmental impact is intertwined with our everyday wardrobe choices?

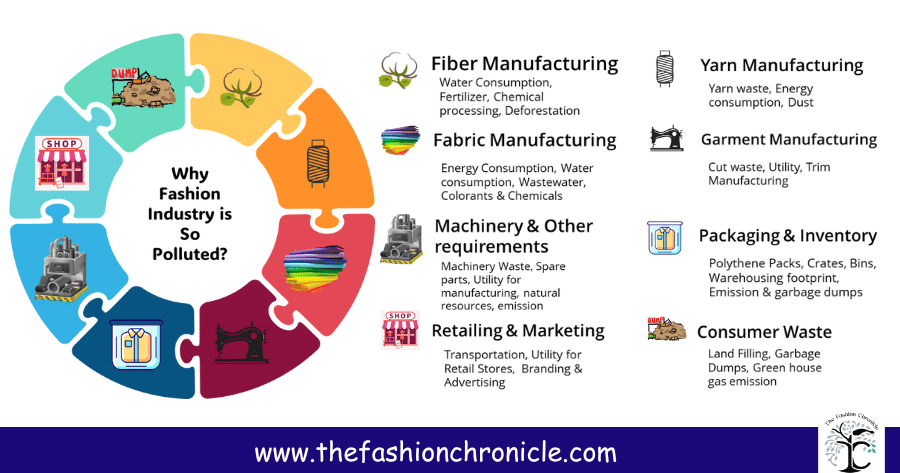

This phenomenon can be attributed to the extensive value stream within the fashion industry. This complex process initiates with the production of natural or synthetic yarns, encompassing the cultivation of natural yarn sources and the synthesis of raw materials required for manufacturing synthetic yarns. As per the latest stats, its clearly demonstrates the remarkable growth in the production of both natural and synthetic fibers, outpacing the rate of population growth.

The production of natural fibers such as cotton, linen, and wool is resource-intensive, particularly in terms of water consumption. Moreover, the land required for cultivation often results in deforestation, with the use of pesticides during the growing process further compounding environmental challenges. Conversely, the manufacturing of synthetic fibers raises concerns related to greenhouse gas emissions and water pollution. Furthermore, the entire supply chain, from converting these fibers into yarn to retailing them for fabric mills, entails various activities, including shipping, transportation, packaging, and waste generation, all of which contribute to the overall environmental footprint.

The subsequent phase in the production chain is one of the most environmentally taxing processes: fabric manufacturing, consisting of two vital stages. Initially, fabric manufacturing primarily entails knitting or weaving, followed by the crucial coloration process, which encompasses dyeing and finishing. Energy consumption emerges as the pivotal aspect in fabric manufacturing, with additional adverse impacts like noise emissions from machinery and waste generation further affecting the environment.

However, it is the coloration process that assumes utmost significance and contributes significantly to environmental pollution. It begins with the critical issue of water consumption during the dyeing process, followed by the substantial energy requirements for operating dyeing machinery. The use of toxic chemicals also exerts a substantial environmental toll. In addition to that there is a process of manufacturing those chemicals and colorants as well. Finally, there’s the matter of wastewater generation; in the absence of a robust wastewater management system, toxic chemicals can find their way into water resources. This underscores the paramount importance of focusing on the environmental sustainability of the coloration process.

The next phase in this production journey leads us to the realm of garment manufacturing. As products transition from yarn mills to fabric mills, we encounter similar environmental impacts during the transition from fabric mills to sewing mills. This stage involves a substantial workforce, and it is imperative for all garment manufacturers to embrace their significant social responsibility toward the welfare of their employees. From an environmental perspective, a significant concern arises from the generation of fabric waste during the cutting process, a notable byproduct of fabric’s transformation into garments. Additionally, there is a pressing issue of air pollution stemming from the combustion of fossil fuels to generate energy. Meanwhile, the sewing process entails the use of various trims such as threads, zippers, buttons, and straps, each of which involves its own set of environmental considerations.

There is a significant environmental footprint associated with the supply chain as well. A variety of packing materials, mainly polythene, are utilized to wrap the final garment. In addition, throughout the garment manufacturing process, a range of polythene and plastic materials are utilized, including chemical barrels and plastic crates and bins. It’s important to highlight that polythene can persist in the environment for several years, presenting an ongoing environmental concern. Following the packaging process, these garments are transported via air freight or sea to distribution centers. While the environmental impact is relatively moderate at distribution centers, there remains a carbon footprint associated with the overall process. Then the products move to retail shops. Moreover, consider the vast retail establishments with their elaborate product display arrangements. These establishments demand significant utility and other resources to create visually appealing product displays. Several of these retail outlets operate 24 hours a day, featuring vibrant and enticing setups designed to attract customers. This continuous operation translates into continuous electricity consumption.

It encompasses a diverse range of equipment, including yarn manufacturing machines, knitting and weaving machines, dyeing and finishing machines, heat setting/dryers and curing machines, printing and embroidery machines, sewing machines, fabric and garment testing machines, and more. Each of these machines undergoes manufacturing, necessitates ongoing maintenance and repair during operation with spare parts, and ultimately concludes its life cycle as waste.

Throughout the entire process, various participants manage inventories, utilizing warehouses for stock storage. The duration of inventory retention varies from one week to three months, contingent on the product stage. Maintaining these inventories imposes a notable carbon footprint.

Marketing materials also make a substantial contribution to environmental impact. Yarn manufacturers and other raw material suppliers, comprising dyes, chemicals, machinery, and trims, develop marketing materials. Fabric manufacturers employ marketing materials to promote their fabrics to garment manufacturers. In turn, garment manufacturers use materials for marketing their products to brands, which, in many cases, invest significant resources in advertising to reach consumers, often through grand fashion shows and exhibitions. These factors should all be considered when assessing the environmental impact of the industry.

After all the intricate processes outlined earlier, garments are eventually manufactured. However, the environmental repercussions persist as the associated costs are deposited into dump yards, exacerbating a burgeoning issue. On an annual basis, the textile industry contributes an astonishing 92 million tons of waste, a staggering volume that leaves a profound imprint on the environment. Textiles, once relegated to landfills, decompose at a leisurely pace, emitting methane—a potent greenhouse gas—into the atmosphere. Methane possesses 25 times the heat-trapping capability of carbon dioxide, making it a major driver of climate change. In addition to methane emissions, the decomposition of textiles releases a plethora of harmful chemicals into the environment. These substances have the potential to contaminate groundwater and soil, posing risks to both human health and biodiversity.

This is the paradoxical reality of the fashion industry – it has evolved into one of the most visually appealing yet simultaneously ranks as the world’s most polluted sector. According to statisticians, if current demographic and lifestyle trends persist, global apparel consumption will surge from 62 million metric tons in 2019 to a staggering 102 million tons within the next decade. Consequently, a collective responsibility falls upon manufacturers, brands, consumers, and legal entities at both national and international levels to facilitate a transformation toward a greener fashion industry.

Author:

Dileepa Fernando

MBA, BSc (Industrial Statistics),

Diploma in Textile Coloration & Finishing, Lean Yellow Belt