De-Skilling the Dye Master’s Role in Fashion Industry

Chemistry behind Fashion May 24, 2024

When we purchase a clothing item from a store or online, one of the key factors we check is the colour. “Does this colour suit me?” is one of the main questions we ask when determining the suitability of a garment for ourselves. The skill of the person who makes the colour is so valued that we call them a “Dye Master” in the industry. It is very difficult to find highly skilled dye masters for the fashion industry, which is why it is a highly-paying job role.

The role of a Dye Master is exceptionally unique and highly technical, comprising 80% tacit knowledge and 20% explicit knowledge. This distinctive blend of expertise grants them significant bargaining power within the industry. However, the required knowledge and skills for this role are not systematically documented; instead, they are predominantly acquired through hands-on experience. Aspiring dye masters often shadow veteran dyers for extended periods to gain the necessary insights.

Moreover, the Dye Master confronts new challenges on a daily basis, necessitating the application of their knowledge to devise bespoke solutions. At times, extensive trial and error are required to arrive at the correct answers. Consequently, replacing a Dye Master’s role is a formidable task, even when a business is prepared to offer substantial compensation.

Fashion Industry Dye Masters: A Highly Skilled and Highly Paid Job Role

Dye Masters are responsible for creating the colours of the fabrics that we wear. They use their knowledge of chemistry and textiles to create a wide range of colours and effects. Dye Masters play an essential role in the fashion industry, as they help to create the clothes that we love to wear.

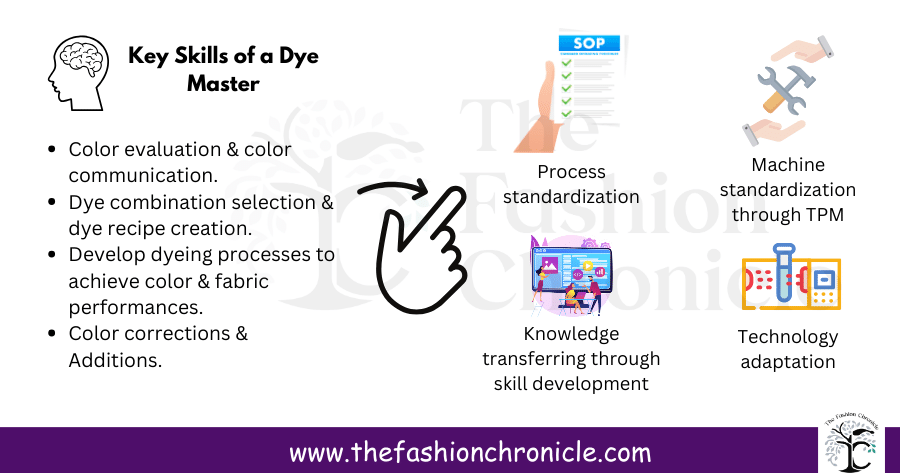

Here are the key skills that a dye master should have:

- Colour evaluation and colour communication skills:

Dye Masters must be able to accurately evaluate and communicate colours. This includes being able to identify different shades and hues, as well as being able to communicate these colours to others in a clear and concise way. He must follow the industry standards.

- Skill of dye combination selection and recipe creation:

Dye Masters must be able to select the right dyes and combine them in the correct proportions to create the desired colour. This requires a deep understanding of colour chemistry and the properties of different dyes.

- Develop dye process to achieve colour tone, levelness, and colour fastness:

Dye Masters must be able to develop and execute a dye process that will achieve the desired colour tone, levelness, and colour fastness. This requires a thorough understanding of the dyeing process and the factors that can affect the outcome. Finally, it should meet the customer’s requirements.

- Skill of colour correction when the bulk colour goes wrong:

Dye Masters must be able to identify and correct colour problems when they occur. This requires a deep understanding of colour theory and the chemistry of dyeing. Even when the recipes are 100% accurate, the colour of a fabric can be slightly changed due to other factors such as water quality, differences in machinery, dye and chemical lot changes, and inconsistent fabric quality. Therefore, Dye Masters must be able to make quick and accurate decisions about how to correct the colour within a limited time.

How to Standardize the Dye Master Job Role

- Standardize colour evaluation and colour communication skills:

Colour evaluation and communication are pivotal tasks that require a clear and precise vision. Individuals involved in this field must pass the Munsell test (eye test), possess acute colour perception, and have the ability to discern even the slightest colour variations. Furthermore, maintaining optimal eye health is essential, as individuals with colour vision deficiencies, such as colour blindness, cannot pursue careers as colourists or Dye Masters. Fortunately, modern technology offers a solution in the form of a “spectrophotometer”. Leading industry giants like “Datacolor” and “X-Rite” provide state-of-the-art spectrophotometers for colour evaluation. These devices offer accuracy levels of up to 70% to 80%, making them invaluable tools for individuals seeking to assess and communicate the colour of a given sample. Spectrophotometers have democratized colour analysis, allowing even the average person to engage in this critical process.

- Standardize the skill of dye combination selection and recipe creation:

The process of dye combination selection is a crucial aspect of a dye master’s work, and it remains a challenge to automate. Spectrophotometers, however, play a pivotal role in streamlining this task. These devices are equipped with software capable of predicting dye recipes with an impressive accuracy rate of up to 70%. The software operates by initially building a comprehensive database that records the colours produced by each dye at varying concentrations.

Creating this database requires precise data input for each dye’s concentration, conducted using a standard fabric. This step is of paramount importance, as the accuracy of subsequent dye formulations hinges on the quality of this data. When a customer requests a specific colour, the software leverages the database to assess the colour and generate a recipe.

However, it’s important to note that the software and spectrophotometer lack an understanding of the intricacies of the dyeing process; they primarily focus on colour matching. The art of dyeing involves numerous technicalities and theories specific to each dye and its application. Therefore, it is incumbent upon dye houses to meticulously document these theories and develop a recipe matrix for every colour tone and fabric type. This matrix should undergo daily updates, and over time, typically within one to two years, it evolves into a valuable resource that aids in standardizing the selection of dye combinations.

- Standardize the skill of Developing the dye process.

This is a fundamental task that involves a wealth of theories and practical knowledge, which dye masters accumulate over extended periods. Whenever they encounter colour-related challenges, they amass knowledge and apply it to refine their dyeing processes. Consequently, the training of the next generation of dye masters is imperative in this field, and it’s essential that these training efforts are well-documented. Each dye house should create its own continually updated training manual.

In this regard, chemical and machine suppliers play a significant role by providing valuable information alongside their products. Dye house personnel should carefully analyze and incorporate relevant data into their training manuals from these suppliers.

In today’s era, dye machines offer advanced technological capabilities in this domain. They enable the recording of the dyeing cycle’s history within the machine or computer data storage, facilitating data collection. However, the data, when presented in raw form, may not be as useful and people in the dye house should analyze those data and conclusions should be incorporated into their training manuals. Modern dye machines provide the functionality to link each machine to a centralized operation location. Here, all dye programs can be stored in one central repository and duplicated to each dye machine. Dye houses can establish a library of the dye processes and programs for which they have in-depth knowledge. These programs can be referenced in the training manual to guide the selection of the appropriate dye program for specific colour-fabric combinations.

- Standardize the Skill of colour correction when the bulk colour goes wrong.

Dyeing is a complex chemical process that takes place in a closed, pressurized, high-temperature environment. The result can only be obtained after several hours, and it is impossible to closely monitor the results throughout the process. Machine operators can only monitor some of the parameters, such as pH value, temperature, and water level. Some parameters are very difficult to check at regular intervals, such as incoming water quality, quality of dye stuff and chemicals, and condition inside the machines. Temperature sensors, pH probes, and water level sensors are also not 100% accurate. In addition, there can also be human errors involved in the process of dying which is not 100% automated. Therefore, there can be slight variations in the colour after the dyeing cycle.

Dye masters are required to give colour corrections, which we call “additions”, to get the colour within a limited time. The ability to give these colour corrections is a valuable skill of a Dye Master. However, this job can be very difficult and stressful, as most dye houses operate 24 hours a day and Dye Masters need to be available to physically review samples and give corrections. Therefore, standardizing this skill is very helpful in achieving work-life balance for Dye Masters.

When standardizing colour corrections, the first step is to identify the parameters that affect the colour the most. If the correct colour can be obtained the first time, there is no need to involve the Dye Master in the next step. Modern dye houses keep this “right first-time (RFT)” rate above 98%. Tools such as the 80-20 rule can be used to easily identify the most critical parameters. Once the most critical and influential parameters have been identified, they can be fixed and monitored over time. Parameters such as incoming water quality, raw material quality, pH accuracy, temperature accuracy, and water level accuracy should be monitored with routine audits. Necessary technical improvements must be implemented to keep these parameters constant over time.

Next, machine standardization projects, such as total productive maintenance, need to be implemented to reduce and eliminate machine-to-machine variations. In addition, quality management systems such as ISO 9001 will also be helpful in the standardization process. The improvement of machine operator skills is also required through consecutive training and refresher sessions. Proper evaluation schemes and incentive schemes can also be used to increase the accuracy of the machine operators. Today, there are new automated solutions such as auto dosing and central machine monitoring that can help avoid human errors. However, these solutions can be expensive. If these costly innovations are not affordable, a highly skilled workforce is the only solution.

The next step is to standardize the colour correction process. A spectrophotometer is the most suitable equipment for this, and it can generate colour correction recipes the accuracy rate of which is between 70% to 80%. The more data is entered into the spectrophotometer, the better its ability to predict colour correction recipes becomes. Maintaining a history of past colour corrections is also deemed essential, as this information can be used to assist inexperienced individuals in making the final decision based on spectrophotometer readings, visual inspection, and the evaluation of past data.

Conclusion

The role of a skilled Dye Master holds immense value within the fashion industry, where colour plays a pivotal role. In the realm of fashion, colour is an indispensable element that cannot be overlooked. Nonetheless, the art of dyeing involves intricate technology, making it crucial to streamline the training process and reduce the time required to cultivate proficient Dye Masters for the industry. This optimization ensures the fashion world continues to flourish with a rich palette of colours.

Doing so can help to reduce the stressfulness of the job, mitigate business risk, and improve work-life balance for Dye Masters.

Author:

Dileepa Fernando

MBA, BSc (Industrial Statistics),

Diploma in Textile Coloration & Finishing, Lean Yellow Belt